Has good adhesion to substrates such as stainless steel, aluminum alloy, galvanized steel, and aluminum plating, with a pull-out performance of up to 4Mpa.

The coating is corrosion-resistant and can effectively resist corrosion from media such as acid, alkali, salt, and seawater.

Thick coating construction is less prone to sagging and is easier to cover compared to traditional epoxy primer products, reducing the cost of topcoat.

Divided into single component, two-component, and bottom integrated models, there are three products for you to choose from

|  |  |  |

|  |  |  |

Light metal specific epoxy primer is a specialized primer product designed for use on stainless steel, aluminum alloy, and galvanized steel substrates.

The product has the characteristics of strong adhesion and good chemical corrosion resistance, and is suitable for anti-corrosion coating on stainless steel containers, aluminum alloy profiles, and hot-dip zinc aluminum substrates.

|  |  |

Used as a special anti rust primer for the surface of non-ferrous metals (zinc, aluminum, magnesium), and can also be used as an anti rust paint for steel surfaces.

| Color | Zinc yellow, gray white |

|---|---|

| Mixed density | 1.35 kg/L |

| Film thickness | Dry film 50 microns, wet film 110 microns |

| Theoretical usage | 0.15 kg/m ² (based on a dry film of 50 microns) |

| Flash point | 27°C |

| Drying time | Surface dry h ≤ 0.5 hours, actual dry h ≤ 24 hours |

| Mixing ratio | Component A: Component B=10:1 (weight ratio) |

Maturity period | 30 minutes |

| Usage period after mixing | Within 3 hours (after the ambient temperature exceeds 30 ° C, the usage time after mixing should be shortened) |

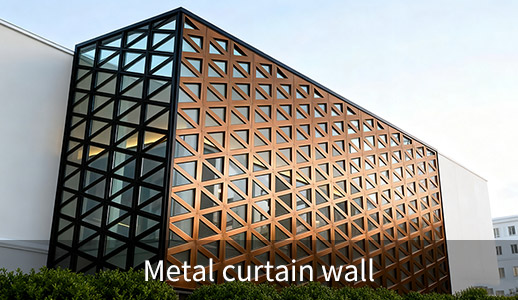

The topcoat uses chlorosulfonated polyethylene, chlorinated rubber, high chlorinated polyethylene, epoxy, acrylic polyurethane, and fluorocarbon external magnetic paint.

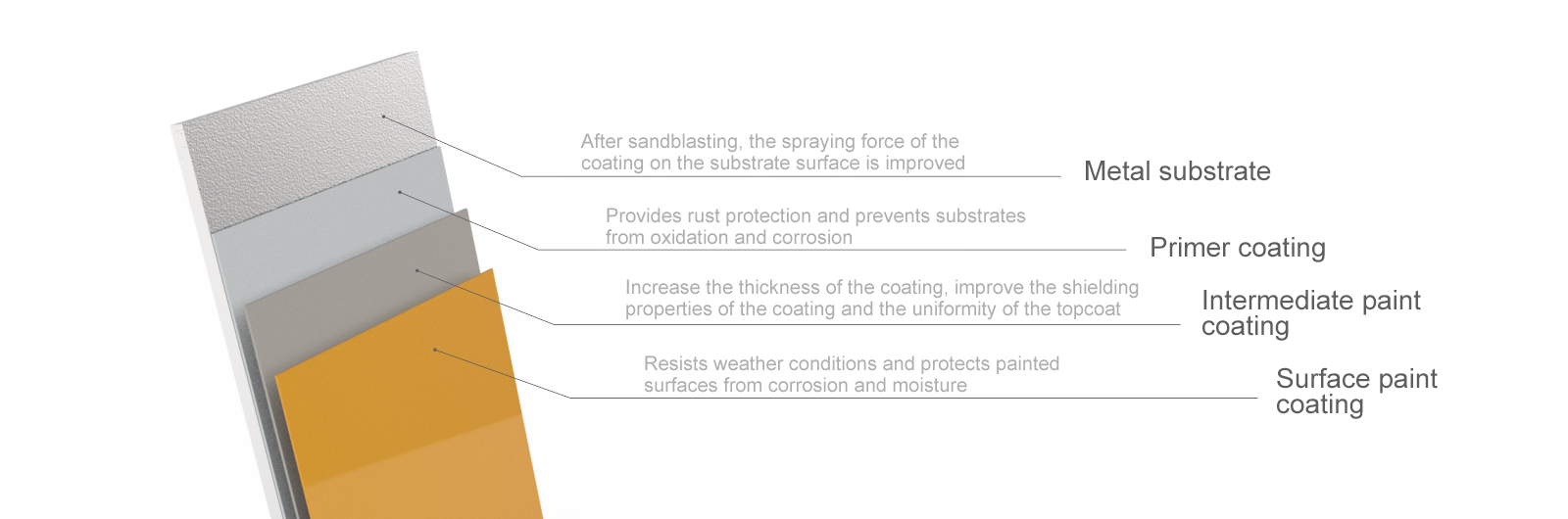

The surface of the coated steel must be thoroughly cleaned of oil stains, oxide scales, rust, old coatings, etc. Shot blasting or sandblasting methods can be used, with a rust removal standard of Sa2.5 and a roughness of 40-75 μ m; Manual polishing and rust removal methods can also be used, with a rust removal standard of St2.0 level and a dull metallic luster exposed on the surface.

1.Smoking and open flames (including lighters and matches), welding, cutting, and other operations that generate sparks or high temperatures are strictly prohibited at the construction site and surrounding areas.

2.Adequate ventilation: Maintaining air circulation in the workplace is the most effective way to dilute flammable and toxic gases.

3.Eye protection: Wear chemical protective goggles or face shields.

4.If paint accidentally touches the skin, immediately rinse thoroughly with soap and plenty of water.

Store in a dry and cool environment, away from heat and fire sources. The storage area must be well ventilated and equipped with fire extinguishers.

This manual is our testing and practical experience, which can be used as a reference for construction. With the continuous improvement and updates of the iron red epoxy rust primer product and materials, please request the latest data for accuracy.

Address: No. 7, Cowboy City 2nd Road, Xintang Town, Zengcheng District, Guangzhou (Room 1011, Building A3, Zhongmao International Building)

Service Hotline:1333-2829-075

Tel:020-32913637

E-mail:kaigetl@163.com

Web:https://www.kaigepaint.com